Box Builders.

|

Bronze Member Username: DomenicoGlendale, AZ USA Post Number: 94 Registered: Apr-09 | ported box for 3 12 inch alpine type r's hight -- 18 width -- 43 depth -- 18 tuned -- 32 port height -- 16 port width -- 4 port length 1 -- 13.25 port length 2 -- 4 any and all input would be great. thinking my port should be bigger but im not too sure. |

|

Silver Member Username: EricmbWaycross, Georgia United States Post Number: 215 Registered: Nov-08 | whats total volume of the box? and how much square port area? |

|

Gold Member Username: TejcurrentPost Number: 1955 Registered: Apr-07 | I came to about 6.54 before port. I'd do a bit more port area if possible- try 16x5 internal measurements. Using that port area I'd figure your port length and adjust back up to around 6ft net- depending on the power and setup- you didn't really mention all that. |

|

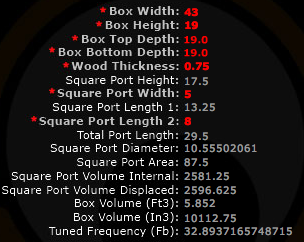

Gold Member Username: Dustin3D&L Audio Tech.Dustin Post Number: 5142 Registered: Oct-05 | i would do something like this:  |

|

Bronze Member Username: DomenicoGlendale, AZ USA Post Number: 95 Registered: Apr-09 | Jones; yeah sorry about not mentioning what the setup will include. ill be runnin 1 pdx 1000 and 1 pdx 600 to the subs & the box is going in the back on an ext cab. &+ thanks bassman |

|

Bronze Member Username: DomenicoGlendale, AZ USA Post Number: 97 Registered: Apr-09 | one more thing, about the demensions.. on the lower left, you know how it says box left plate: 18.25 x 17.5 x 18.25 x 17.5 and box right plate: 17.5 x 17.5 x 17.5 x 17.5 why are those different? shouldnt the left and right sides of the box the same? please help me get a grasp on this shiitt thanks |

|

Silver Member Username: BoomtankRochester, NY USA Post Number: 646 Registered: Oct-06 | wait ur running 2 different amps to subs which are in a common enclosure? |

|

Platinum Member Username: InsearchofbassYork, Pennsylvania Post Number: 12655 Registered: Jun-04 | "box left plate: 18.25 x 17.5 x 18.25 x 17.5 and box right plate: 17.5 x 17.5 x 17.5 x 17.5" (its correct its taking off the thickness of the wood) its because its how they connect to each other |

|

Bronze Member Username: DomenicoGlendale, AZ USA Post Number: 98 Registered: Apr-09 | eddy; yes. 1 pdx 1000 would run two type r's and the pdx 600 would run the other type r. im guessing that shouldnt be done?.. ---------------------- sean; do you think if i would copy all the dementions RD gives me and bring them to a woodshop (home depo) they'd understand that and cut it correct? |

|

Platinum Member Username: InsearchofbassYork, Pennsylvania Post Number: 12667 Registered: Jun-04 | They are supposed to but i hear they dont cut exact. |

|

Gold Member Username: Dustin3D&L Audio Tech.Dustin Post Number: 5143 Registered: Oct-05 | Depends who you get to cut your wood. Some guys at home depot know what their doing and they do everything pretty precise and they have experience using the panel saw, some don't. as long as your cuts are within 1/8-1/16" precision, you will be fine. and yes, I would not run two different amps to different subs, expecially running one sub more power than the other. I would just run the pdx to the subs. |

|

Silver Member Username: EricmbWaycross, Georgia United States Post Number: 224 Registered: Nov-08 | yeah, definitely just use the 1000... |

|

Diamond Member Username: WingmanaliveWww.stainles... .ecrater.com Post Number: 21470 Registered: Jun-06 |

THAT is a loaded statement lol. I've been working with power tools and panel saws for 20+ years. When you pay someone $10/hr at a home improvement store that individual is either retired, out of high school, or waiting for another gig. It CAN be insulting to tell you the truth. In my years, doing what I have, I can cut a sheet of plywood, drive a forklift, recommend a better stain, fix your toilet, and probably balance your checkbook better than the goons they hire there. VERY few know a thing or two. The rest are waiting to punch out. True, good advice costs $$. Something Home Depot or Lowes doesn't have in their budget to employ ppl for. In fact, if they did hire knowledgeable peeps they would probably lose $$ because they would educate ppl on how/where to get things done for themselves instead of hiring their own in house sub contractors to do it for them! |

|

Silver Member Username: WickedbassTheWicked Post Number: 962 Registered: Jan-08 | ^X10000000 Paul for President. I demand it.  |

|

Diamond Member Username: WingmanaliveWww.stainles... .ecrater.com Post Number: 21475 Registered: Jun-06 | Just saying. They are huge because they draw the ppl in. We all love the places right? I do too. It's just that the support is comical at best. I ask for help in the lumber area and get a 17 year old who has major issues with his girlfriend and can't stop talking to her on his cell phone. Then I may need a patio heater that is stored on the top shelf and takes another 45 minutes for the morons to retrieve. The place is full of fail. If I Spent a day and a fully charged video recorder I could fill Youtube with a load of BS. |

|

Gold Member Username: Dustin3D&L Audio Tech.Dustin Post Number: 5144 Registered: Oct-05 | i know what you mean paul. I agree completely. BUT, it really depends on who is there. Because I'v had people do some really nice cuts back in the day when i didnt have my own table saw. |

|

Diamond Member Username: WingmanaliveWww.stainles... .ecrater.com Post Number: 21480 Registered: Jun-06 | Yes there is always an extreme which defines an average. Then again those who know anything won't stay in a Home Depot for long, unless he's hiding from something. I hear ya Dustin, I really do. Shoot if they paid me $20+/hr I would love to cut ppl's wood for them accurately. ALL day. But seeing as they don't....how accurate do you think MOST ppl's cuts are going to be? What sucks is the irony of them not letting you cut your own wood. They say it's for your own safety but it wouldn't matter anyway because their equipment is so far out of whack Norm Abraham himself couldn't cut a straight line lolol. So why go? I know. Some of the girls have nice B(.)(.)BS. |

|

Gold Member Username: Dustin3D&L Audio Tech.Dustin Post Number: 5146 Registered: Oct-05 | haha. i feel ya paul |

|

Bronze Member Username: DomenicoGlendale, AZ USA Post Number: 99 Registered: Apr-09 | With all that being said would it even be worth it to buy another type r (currently have 2) and power all three with a pdx1000? &+ if those f*cks dont cut it right couldnt i just leave and not pay for the wood? rofl  ---------- Thanks; Paul Eric Bassman Sean |

|

Gold Member Username: DuckaShelby Twp., MI United States Post Number: 1266 Registered: Jan-08 |

Yes you could. You do not pay the guy who cuts it. You pay at the register which is on the exact opposite side of the store. If you dont like it just leave the cart and all your wood somewhere. Not sure if it is legal or ethical, but chances are no one will care. If they do care tell them you forgot you left it in the middle of an aisle. Ooops  Vote for |

|

Gold Member Username: Dustin3D&L Audio Tech.Dustin Post Number: 5147 Registered: Oct-05 | There is no need to buy another type r. Just have your two and power them with the pdx and your golden |

|

Bronze Member Username: DomenicoGlendale, AZ USA Post Number: 100 Registered: Apr-09 | Bassman, think you could get me the specs on the RD cal like you did before but this time for 2 type rs not 3, thanks bro ------------------- Ducka, thats what i was plannin' on doing  |

|

Gold Member Username: Dustin3D&L Audio Tech.Dustin Post Number: 5148 Registered: Oct-05 | my computer is not working to well for some reason. do: 37 wide 18 high 16 depth port width = 3 port length 2 = 7 gives you a box around 4.2 @ 32 |

|

Silver Member Username: DomenicoGlendale, AZ USA Post Number: 101 Registered: Apr-09 | thanks a lot dude, lets just hope home depo cuts it right  |

|

Gold Member Username: Dustin3D&L Audio Tech.Dustin Post Number: 5149 Registered: Oct-05 | yea, just tell them you need it pretty prcise. within 1/8 to 1/16" |

|

Diamond Member Username: WingmanaliveWww.stainles... .ecrater.com Post Number: 21484 Registered: Jun-06 | If you have to draw the lines for them. Borrow a drywall square in a different isle and measure it and draw it on for them. I think you'll be surprised at how different the saw and square will be. Tell them you trust the square more. And don't worry about abandoning pieces of MDF. Until you pay for it the wood isn't yours anyway lol. They cut up scraps all the time and sell them into 2' X 4' pieces. Not to mention all the waste employees generate on their own. The biggest concern those chains have is theft. Not from the customers but their own employees! They'll spend $1000s on cameras and security to watch themselves instead of you. You know that guy/girl who wishes you a good day on your way out the door? THAT'S the security for customers. It's a joke. You could literally walk right by the cashier holding a $400 nail gun, sensors going off, and they can't do a thing about it except try and get your plate # when you drive off. By law they can't physically assault you as a common employee. The under cover security guards are there watching all the poaching going on by the ppl in orange and red vests. So don't feel bad making him cut it again and again and again.  |

|

Silver Member Username: DomenicoGlendale, AZ USA Post Number: 102 Registered: Apr-09 | Thanks bassman and paul  i copied the demensions that are on the RD cal and im goin' in there and giving them the paper and telling them if its not exact shove it up yr azz hahaha  Do you guys know what PL is? its next to liquid nail its like liquid nail but x10000 stronger. We use it when we do repairs on Turf, i was thinking about using that instead of liquid nail and to make it air tight i was thinking...hot glue gun? "hahah" |

|

Gold Member Username: Dustin3D&L Audio Tech.Dustin Post Number: 5150 Registered: Oct-05 | use titebond II for the glue and just silicone for the inside of the enclosure. |

|

Silver Member Username: DomenicoGlendale, AZ USA Post Number: 107 Registered: Apr-09 | okay, im going to upload pictures of my current system and box and where its going.. all that jazz when i get my wood ill make a build log. hope yall like it thanks too; Bassman! Paul! Eric! Troy! Ducka! Sean! Eddy! |

|

Gold Member Username: Dustin3D&L Audio Tech.Dustin Post Number: 5151 Registered: Oct-05 | No problem. good luck on the project! Make sure to pre-drill + countersink and use 1 5/8" coarse thread drywall screws |

|

Silver Member Username: DomenicoGlendale, AZ USA Post Number: 108 Registered: Apr-09 | noob ? = what do you mean predril? & just to make sure, cut the holes at 12inch? |

|

Silver Member Username: DlavanteD&L Audio Tech. , Daniel Corvallis, O... Post Number: 246 Registered: Feb-07 | the holes will be 11" |

|

Silver Member Username: DomenicoGlendale, AZ USA Post Number: 109 Registered: Apr-09 | figured so, just making sure  |

|

Silver Member Username: DomenicoGlendale, AZ USA Post Number: 110 Registered: Apr-09 | another question, how far apart should the port and holes be from each other? |

|

Gold Member Username: Dustin3D&L Audio Tech.Dustin Post Number: 5152 Registered: Oct-05 | doesn't really matter. You can decide on where you want the sub holes at the very end when you jig saw or router the holes out. and before you put the screws in, you need to pre-drill with a drill bit. use a 1/8" bit or something similar. then after, countersink the hole then put the screw in |

|

Silver Member Username: Simple_smithLapeer, Michigan United States Post Number: 130 Registered: Dec-08 | If you don't pre-drill, it'll split the wood. splitting = fail |

|

Silver Member Username: DomenicoGlendale, AZ USA Post Number: 112 Registered: Apr-09 | well you guys were right, home depot is full of morons... i gave this kid the specs and he was cutting my wood while i was getting titebond and everything. once i come back to get my wood i notice that every side is curved... i asked him wtf he was doing when he was cutting the wood and he told me to get a sander to make them straight.. (my head almost explaoded) i asked for the specs back and told the guy that hes a f*ckin idiot. i went to another homee depot to get the wood cut (did not pay for the old wood) once i got to the other home depot i had this other dude cut it and he did an awesome job. but when the kid cut my port length he cut it 0.75 to short. so... i have to go back and get my ports cut again and once i get all that done i can go ahead and start building.  |

|

Diamond Member Username: WingmanaliveWww.stainles... .ecrater.com Post Number: 21491 Registered: Jun-06 | Pics pics pics. |

|

Gold Member Username: Wolf_houndPhoenix, AZ Post Number: 1061 Registered: Sep-05 | did you go to the home depot by the 101? |

|

Silver Member Username: DomenicoGlendale, AZ USA Post Number: 117 Registered: Apr-09 | Sorry i havent been on to upload the pictures, im going to be uplaoding pictures today and a video... if i can find the camera usb cord haha yeah its by the 101,but there is alot by the 101 i went to 6160 W. Behrend Dr. (623)376-0278 if you are planning on going ask for KEV(nametag) |

|

Silver Member Username: DomenicoGlendale, AZ USA Post Number: 119 Registered: Apr-09 | okay i finnaly got the pic uploaded to my comp, i made a quick video when i went to my car to get my camera. hope you guys like it heres a picture of the first moron that tried to cut my wood <img> heres all the supplies that i used <img> got the wood home (: <img> stood eveything up just too see how itd look when i was done <img> 7am started gluing (dont recomend this way) <img> got the sides all guled and drying <img> template all drawn out and ready to go <img> holes cut <img> gluing front side on <img> got all sides on and port glued and ready <img> installed speakers <img> VIDEO <embed> |

|

Gold Member Username: Dustin3D&L Audio Tech.Dustin Post Number: 5154 Registered: Oct-05 | Ok. some suggestions: (constructed criticism) 1. If your going to use silicone, easy up on it, all you need is to do the corners, don't lay it on so thick. Just a finger tip spread across the corners. 2. Your screws are way too close together... each screw should be 3-4 inches apart. not 1.5" like you have. 3. It looks like your top of the box was cut wrong, and for some reason the top baffle is flush with the front baffle..??? the top baffle is suppossed to be the size of the bottom baffle (i.e. the size of the length & width of the box) When using titebond, its important to remember that when the glue dries, that bond is actually stronger than the bond and wood its self (which means you can lose less screws and pretty much all the screws are doing in the first place are just holding the joints together until the glue dries. other than that, nice work. video? |

|

Silver Member Username: DomenicoGlendale, AZ USA Post Number: 120 Registered: Apr-09 | thanks for the tips dustin, ill be sure to keep them in mind when i do my other boxes. and about #3.. will that effect proformance? Theres the video http://www.youtube.com/watch?v=jRVh5cSSKM8 |

|

Gold Member Username: Dustin3D&L Audio Tech.Dustin Post Number: 5155 Registered: Oct-05 | no it wont. it just took away some cuft from the box but not much. looks good though, how do you like it? You might want to cover the box in something as well... or put a finish on it.... |

|

Silver Member Username: M0nstarToledo, OH U.S. Post Number: 371 Registered: Dec-08 | try having them face the back of the car?... copy & paste from youtube comments lol |

|

Silver Member Username: DomenicoGlendale, AZ USA Post Number: 121 Registered: Apr-09 | Dustin; i love it! it makes sooo much of a difference. i was thinking about black suede for the box to match my headliner. thanks for all the help man! MisterLDR; i was planning on putting them face the back of the truck but it was such a b!tch to put it in the car when my brother and i was struggling to put the box in we dropped it like that and thats how it stayed lmaowhen im done working on the trans i will turn them around. |

|

Platinum Member Username: InsearchofbassYork, Pennsylvania Post Number: 12743 Registered: Jun-04 | Looks like it turned out decent |

|

Silver Member Username: DomenicoGlendale, AZ USA Post Number: 122 Registered: Apr-09 | thanks sean, as i build more i should become pro |

|

Silver Member Username: DomenicoGlendale, AZ USA Post Number: 124 Registered: Apr-09 | thanks sean, as i build more i should become pro |

|

Gold Member Username: Basebalz13Moneta, Va Usa Post Number: 1869 Registered: Aug-07 | werd to yo momma |

Main Forums

Today's Posts- Home Audio Forum

- Home Video Forum

- Home Theater Forum

- Car Audio Forum

- Accessories Forum

- All Forum Topics