Carpenters....how can i cut it like this????

|

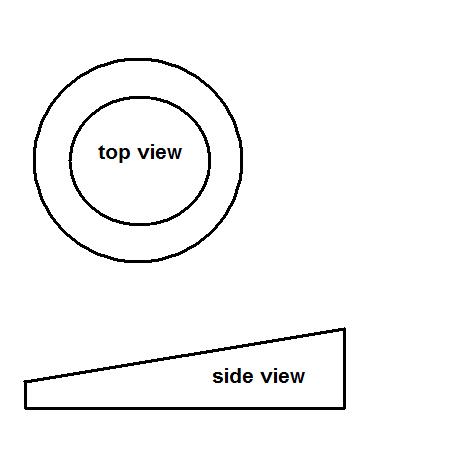

Platinum Member Username: BestmankindHttp://www.rdaudio.net... Post Number: 19367 Registered: Oct-05 | i want to cut a mdf ring. but i need it to be angled so i can angle my speakers. here is a picture of what i am talking about.  |

|

Platinum Member Username: Rovin4 10 Pioneer... Post Number: 13350 Registered: Jul-05 | looks like a bandsaw would be the best thing to cut that angle safely (im guessing they would have a jig to hold it firmly\safely....u better check a woodworking shop & have them do that for u ..... |

|

Platinum Member Username: BestmankindHttp://www.rdaudio.net... Post Number: 19372 Registered: Oct-05 | thats what i was afraid of rovin. lol. |

|

Gold Member Username: InsearchofbassPost Number: 8446 Registered: Jun-04 | well first you cut around the ikea ad then you cut around the ipod media player ad...ecoustics has lost it if they thought this was a good idea with these ads the way they are in the posts...sorry Chad just venting |

|

Silver Member Username: BonhamdNorthern, Michigan USA Post Number: 518 Registered: Nov-07 | maybe this is a lazy way or a stupid thought but... possible shim it to the angle that you want and then apply your fleece and resin to fill in the gaps? |

|

Platinum Member Username: BestmankindHttp://www.rdaudio.net... Post Number: 19373 Registered: Oct-05 | well if you see the picture below, i circled the part. see how it angles away? first of all, i want to add a mdf ring there so that speakers sticks out to match the mid. also i want to get rid of that angle so it faces straight.  |

|

Gold Member Username: Stateprop486PA Post Number: 1143 Registered: Jan-08 | http://cgi.ebay.com/6-5-3-4-MDF-Large-Directional-ANGLED-SPEAKER-RINGS_W0QQitemZ 310030799066QQihZ021QQcategoryZ50552QQssPageNameZWDVWQQrdZ1QQcmdZViewItem |

|

Platinum Member Username: BestmankindHttp://www.rdaudio.net... Post Number: 19376 Registered: Oct-05 | lol too expensive. |

|

Gold Member Username: Stateprop486PA Post Number: 1144 Registered: Jan-08 | lol u could email them and ask what they use to cut it. lol |

|

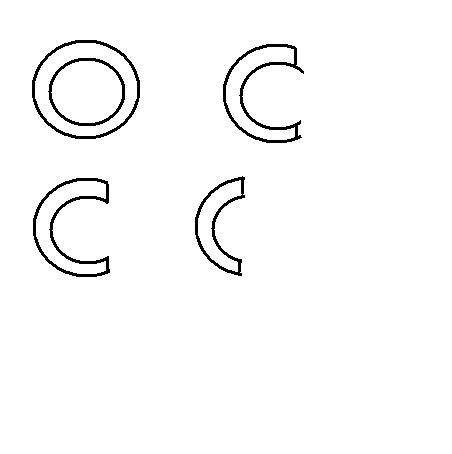

Platinum Member Username: BestmankindHttp://www.rdaudio.net... Post Number: 19379 Registered: Oct-05 | how about i make it like this and stack it on top of each other. then i can use resin to fill in the gaps. finally sanding it down to a smooth finish. the first ring would be with a 3/4 mdf and the rest would be with something thinner.  |

|

Silver Member Username: BonhamdNorthern, Michigan USA Post Number: 519 Registered: Nov-07 | seems like a good idea to me. give it a try. |

|

Gold Member Username: Th3pwn3rPost Number:... Post Number: 7340 Registered: Jul-06 | Chad, try cutting a ring with a 12'' mitre saw straight down at an angle. That might give you the offset you're looking for. |

|

Gold Member Username: Th3pwn3rPost Number:... Post Number: 7341 Registered: Jul-06 | Hmmm...that might be a bit dangerous though. I'm sure there's a planer you can use for that. |

|

Platinum Member Username: BestmankindHttp://www.rdaudio.net... Post Number: 19380 Registered: Oct-05 | yeah. man no one told me getting everything right is alot of work. lol. i am not concerned about the sq cause its the woofer. you don't really need to point the woofers. but its the looks. i need the bling bling. us azns love bling bling. lol. |

|

Gold Member Username: Th3pwn3rPost Number:... Post Number: 7342 Registered: Jul-06 | Well, you can try using a jigsaw as well. Just mark a line all the way around where you want it to tape off and cut it larger than needed and file or sand it down to get it level. |

|

Platinum Member Username: BestmankindHttp://www.rdaudio.net... Post Number: 19382 Registered: Oct-05 | oh yeah thats right. lol. jig saw. hahahahahahahaha. why didn't i think of that. damn. ima do that saturday. thanks rob. |

|

Gold Member Username: Th3pwn3rPost Number:... Post Number: 7344 Registered: Jul-06 | And if you can, clamp the ring down to the edge of a table and cut it like that. Should be the best way...well it's the best way I can think of right now. |

|

Platinum Member Username: BestmankindHttp://www.rdaudio.net... Post Number: 19383 Registered: Oct-05 | btw i really mean that. i wasn't being sarcastic. just in case you thought that i was, i am telling i wasn't. lol. seriously. |

|

Gold Member Username: Stateprop486PA Post Number: 1145 Registered: Jan-08 | "us azns love bling bling" lmao...yes we DO!! |

|

Gold Member Username: Safe_crackerChicago, IL US Post Number: 4294 Registered: Jan-06 | Hold up you mid to the angle you want, now measure the space that needs to be filled. Now cut a few MDF rings to suit the mid, glew them together. Once dry draw the line from zero to the measure ment you fount will look like a slope. Now use a straight saw to cut on that line you will be left with what you need. Polo.. |

|

Platinum Member Username: Rovin4 10 Pioneer... Post Number: 13353 Registered: Jul-05 | ^that could work how about u glue 2 rings together & if u have a belt sander then put 1 screw on the higher side of the ring to hold in place on ur work table table while ur sanding it down to the angle u need ..... |

|

Gold Member Username: Killerzracing71Fredericksburg, Virginia United states Post Number: 2027 Registered: Aug-05 | [IMG]http://i267.photobucket.com/albums/ii306/Killerzracing71/untitled.jpg[/IMG] I would do this GLASS MAN..... that pic is a side view 2 Mdf Rings a little piece of MDF to give you the angle you want Then i would get a Can or some cylindrical object same I.D (inner dia) as the O.D. (outer dia) as the MDF so it can slip over the mdf and seal it up there you go You good at glass so do it that way so you only have to seal up the top part of the Ring |

|

Platinum Member Username: BestmankindHttp://www.rdaudio.net... Post Number: 19389 Registered: Oct-05 | okay the link to the pic don't work. |

|

Silver Member Username: Surferdude9371Im BTL Bumpin Post Number: 782 Registered: Mar-07 | set table saw to correct angle easy and safe |

|

Silver Member Username: Surferdude9371Im BTL Bumpin Post Number: 783 Registered: Mar-07 | hell of a lot easier to cut the dowels to the corect angle plus gives you more support for the screws |

|

Platinum Member Username: BestmankindHttp://www.rdaudio.net... Post Number: 19390 Registered: Oct-05 | oh i see what you are saying. you mean just cut a ring and make dowels to the angle i want. lol. good idea also. |

|

Silver Member Username: Surferdude9371Im BTL Bumpin Post Number: 784 Registered: Mar-07 | ya i looked into doing fiberglass work thats what all the "pros" do they use angled dowels. if you angle cut the circle it will be alot weaker to mount the speaker |

|

Platinum Member Username: WingmanaliveA pic is worth 1000 posts!! Post Number: 14890 Registered: Jun-06 | Rovin has a good angle. Safe too. Use dust masks and cut the ring. I would shape it with either the belt sander or benchtop unit. Applying enough pressure but not too much. Takes time but at least there are no blades involved. |

|

Silver Member Username: Surferdude9371Im BTL Bumpin Post Number: 786 Registered: Mar-07 | ya worst case you sand your hand down to the bone lol stick with the dowels once fiberglass dries you can remove them use hot glue to mount the dowels |

|

Platinum Member Username: WingmanaliveA pic is worth 1000 posts!! Post Number: 14894 Registered: Jun-06 | Naw lol. Use a coarse grit paper and the material would come off quick. |

|

Gold Member Username: Van_manBoston South, MA Post Number: 3674 Registered: Mar-06 | belt sander with 60-80 grit and about 3 minutes of power. then finish off with 120-180 grit |

|

Platinum Member Username: WingmanaliveA pic is worth 1000 posts!! Post Number: 14900 Registered: Jun-06 | Yyyyyyyup. |

|

Platinum Member Username: BestmankindHttp://www.rdaudio.net... Post Number: 19401 Registered: Oct-05 | sanding it down is cool but isn't it hard to get the pricision down when sanding? at least when you cut stuff, you can cut along the lines. then sand the inperfections. |

|

Platinum Member Username: WingmanaliveA pic is worth 1000 posts!! Post Number: 14902 Registered: Jun-06 | That's the beauty of sanding Chad. You have control over how much you take off, a little at a time. When you saw half way through and realize you're off even a little bit it's a fubar situation. Sanding is more like a freehand art form. With some control it can be used to shape wood into rounded surfaces too. |

|

Gold Member Username: Nd4spd18Northwest PA Post Number: 6812 Registered: Jul-06 | " lol too expensive " Is this the same Chad Lee who was going to buy a plane ticket to fly across the country to come to our NE meet, but didn't because they didn't have any first class seats and he wouldn't get coach. |

|

Platinum Member Username: BestmankindHttp://www.rdaudio.net... Post Number: 19402 Registered: Oct-05 | lol paul you make it sound so dramatic. M.S. lol. its just i can't justify spending 20 bux plus shipping for a mdf ring. its the pricipal. lol |

|

Platinum Member Username: WingmanaliveA pic is worth 1000 posts!! Post Number: 14936 Registered: Jun-06 | The right tool is gold Chad. |

|

Silver Member Username: MesodummTri-City, Az Usa Post Number: 443 Registered: Apr-07 | just cut your ring out normal and use a belt,disk or hand grinder to get the angle |

|

Gold Member Username: HdubbTeam Revolution Post Number: 3449 Registered: Nov-04 | a bench disk sander would be perfect for this! |

|

Platinum Member Username: Rovin4 10 Pioneer... Post Number: 13359 Registered: Jul-05 | see !? every1 kinda leans towards my brilliant idea ! .....  |

|

Gold Member Username: Killerzracing71Fredericksburg, Virginia United states Post Number: 2030 Registered: Aug-05 | the pic worked for me...... idk about e sometimes lol |

Main Forums

Today's Posts- Home Audio Forum

- Home Video Forum

- Home Theater Forum

- Car Audio Forum

- Accessories Forum

- All Forum Topics