My Box for my Mag 15s

|

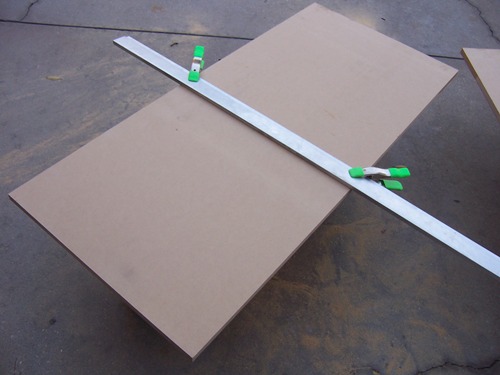

Gold Member Username: Tdeaton1021Near Tampa, Florida USA Post Number: 3184 Registered: Sep-04 | Here she is! Oh, you wanted completed pics? I'm kinda hungry. maybe after i eat I'll go out there and build it 8)  Below is how i make all my cuts. I measure six times, use a straight edge, cut once.  follow my measure 6 times cut once method and you'll get results like this. perfect.  |

|

Gold Member Username: RovinTrinidad & T... Post Number: 9684 Registered: Jul-05 | i thought the proverb was "MEASURE TWICE , CUT ONCE" not measure 6 times ,cut once -lol but i hear u since i too measure about 3 times b4 i cut ..... |

|

Gold Member Username: Tdeaton1021Near Tampa, Florida USA Post Number: 3190 Registered: Sep-04 | It is lol. but i found that measuring 6 times was more effective and yet more efficient because i NEVER have to recut a piece. (btw, i like all my cuts to be REALLLY close, i dont want any gaps AT ALL) home depot told me they could only cut within 1/8" i was like okay i'll cut them myself thank you lol. all my cuts are within like 1/64" lol. yeah i guess thats kind of rediculous but i like it 8) |

|

Gold Member Username: 54danny54Betsy layne, Kentucky..GO... \blink, red,... Post Number: 2847 Registered: Nov-04 | ur ghay trevor, WE NEED COMPLETED BOX PIX DAMNIT lol |

|

Gold Member Username: BestmankindFi AudioBTL Post Number: 6944 Registered: Oct-05 | damn you perfectionist. nice looking cuts btw. |

|

Gold Member Username: Tdeaton1021Near Tampa, Florida USA Post Number: 3192 Registered: Sep-04 | I got lazy after I ate. I'll finish it tomorrow :-P |

|

Gold Member Username: Basshead86Chrome Dip it & Ship i... Post Number: 8427 Registered: Aug-05 | ehhh. i guess we will just have to wait.........................*sighs*.................. |

|

Gold Member Username: Tdeaton1021Near Tampa, Florida USA Post Number: 3211 Registered: Sep-04 | Here she is... look ma, no screws!  hadn't sanded off the wood filler yet... (btw, it feel really cool to stand INSIDE your port. at that moment, you know its a monster 8) )   |

|

Gold Member Username: B101USA Post Number: 3729 Registered: Sep-05 |  looks good... I do undsertand... measure measure measure... nothing wrong with perfecting ur skills.. looks good... I do undsertand... measure measure measure... nothing wrong with perfecting ur skills.. damn that box looks tasty, back of the escalade?? I already have a excellent idea on how that is goin to sound.... we did a escalade with a box similar to that size, and he had 2 1200d amps on each sub, and it straight got down low and dirty for some audiobahn....  so I can imagine the mags.... so I can imagine the mags.... nice curves on the ports, seen u been quite busy... |

|

Gold Member Username: Tdeaton1021Near Tampa, Florida USA Post Number: 3214 Registered: Sep-04 | Thanks B :-) and yup, back of the Caddy! I may be picking up a new product line for my business so as soon as thats over I can start ordering my new HU, epic160, Amp, alternator, etc. damn, I cant wait! |

|

Gold Member Username: B101USA Post Number: 3731 Registered: Sep-05 |  daymn... sounds like ur in for madd fun... epic 160 looks real good too, but i have the epic-center already... but I was told its still the same, but I would like the meter... daymn... sounds like ur in for madd fun... epic 160 looks real good too, but i have the epic-center already... but I was told its still the same, but I would like the meter... good luck on the project... Im gettin ready to put together a stupid stupid system... but I got setback, cause the car dealer try to steal my $$, and im still very upset, so if I dont get it back, I will be in jail for a very long time...  |

|

Gold Member Username: Dustin3Tigard, OR U.S. Post Number: 4117 Registered: Oct-05 | is that angle thing at the end of the prot held on by just glue? JW |

|

Gold Member Username: Tdeaton1021Near Tampa, Florida USA Post Number: 3218 Registered: Sep-04 |  nope, there are screws. but what many people dont know is that the main purpose of screws is just to hold the wood tightly together while the glue drys. |

|

Gold Member Username: BestmankindFi AudioBTL Post Number: 7010 Registered: Oct-05 | awesome box. |

|

Silver Member Username: BoomtankPost Number: 114 Registered: Oct-06 | Nice box. Ill be making my dual 15 vented sunday ill post pix. It will be for 2 ssd's for now but im putting 05 kicker comp 15's in till i by the ssd's. Then 2 months for my 2 BTL F/L and orions Can't wait for all that xmas money  |

|

Gold Member Username: Basshead86Chrome Dip it & Ship i... Post Number: 8497 Registered: Aug-05 | awesome box Trevor VERY NICE. and i too don't understand why people go NUTS with the screws...they are there JUST to hold the box tightly together until the glue dries as you said. hell my shop owner used a staple gun......never had leaky boxes... |

|

Gold Member Username: Tdeaton1021Near Tampa, Florida USA Post Number: 3219 Registered: Sep-04 | Thanks for the compliments guys! makes the work feel even more worth while. Eddy, did i understand you correctly? your buying ssd's and in 2 months getting BTLs? lol why wouldnt you just go straight to the BTLs? muddy- yeah i was thinking about using a brad nailer actually for the "V" in the back of the port. i couldnt find it though. i think my dad may have taken it back lol. |

|

Gold Member Username: B101USA Post Number: 3733 Registered: Sep-05 | i would still thro some screws in there, especially if ur gonna put some power to that box... just fill the screw holds with bondo and sand everything back down after.... i know the glue hold the boxes, but in 1 year just the carpet will be holding the boxes... I see this alot with prefab boxes and no screws... lol alot of resonance start to occur when pannels get loose... I also think it has alot to do with the types of glues used.... |

|

Gold Member Username: Basshead86OG eCoustics Member Post Number: 8533 Registered: Aug-05 | Liquid NAils FTW!!!!!!! |

|

Gold Member Username: RovinTrinidad & T... Post Number: 9706 Registered: Jul-05 | nice box i use 2" drywall screws like every 4.5-5" & liquid nails .... |

|

Gold Member Username: Tdeaton1021Near Tampa, Florida USA Post Number: 3246 Registered: Sep-04 | yup. i used 2.5 inch course drywall screws and liquid nails. B, there are screws through out the entire box, i just countersunk them and filled the hole with wood filler. and besides, i wont need any screws, the entire thing is going to be resined so it will be VERY strong.  |

|

Gold Member Username: RedlinerWilmington, Ma Post Number: 2867 Registered: Jun-05 | it looks really nice trevor when u get it in give us a review on those mag's cause i am thinking of grabbing one |

|

Gold Member Username: 54danny54Betsy layne, Kentucky..GO... \blink, red,... Post Number: 2862 Registered: Nov-04 | lol those are sum fugly feet. but man thats a nice a ss box. |

|

Silver Member Username: BoomtankPost Number: 115 Registered: Oct-06 | Im buing the ssd's first cause im selling them to my friend with a box for 600 bucks after i get my btls  ill make about 150 bucks profit and get to use them for a while first. ill make about 150 bucks profit and get to use them for a while first. |

|

Gold Member Username: Extrmndor3Friday, Str8t to the Gentlemans club Post Number: 2543 Registered: Feb-06 | lookin good man |

|

Gold Member Username: Tdeaton1021Near Tampa, Florida USA Post Number: 3252 Registered: Sep-04 | actually, a girl has actually complimented me on my feet before. it was kinda weird... but you can STFU!  |

|

Gold Member Username: Basshead86OG eCoustics Member Post Number: 8545 Registered: Aug-05 | wow.....never thought i would see the day that someone would be defending their feet on the forum . lmao! |

|

Silver Member Username: Waterboy2289Martinez, Georgia USA Post Number: 133 Registered: Jan-06 | Trevor, do you use a circular saw to cut the boards for your box? That's how I do it; clamp a straight edge down, then run the circular saw down it- poor mans table saw....haha |

|

Gold Member Username: Tdeaton1021Near Tampa, Florida USA Post Number: 3265 Registered: Sep-04 | yup, thats how i do it matt. ever seen a saw stop table saw though? It's badass. |

|

Gold Member Username: BestmankindFi AudioBTL Post Number: 7045 Registered: Oct-05 | any updates trevor? i need more pics. i can't live without sub box pics. |

|

Bronze Member Username: PitbullguyChi Town Post Number: 48 Registered: Oct-06 | the second toe should extend past the big toe....f!@#ing freak. j/k  nice box nice box |

|

Gold Member Username: Tdeaton1021Near Tampa, Florida USA Post Number: 3267 Registered: Sep-04 | I'll give you some pics tomorrow. really not anything new today. I think I'm going to start the resining process tomorrow  |

|

Gold Member Username: Tdeaton1021Near Tampa, Florida USA Post Number: 3268 Registered: Sep-04 | Crown- The second toe shouldn't be longer. thats why they call it the "big toe". yall are jus upset because you cant stand in your port  |

|

Bronze Member Username: PitbullguyChi Town Post Number: 50 Registered: Oct-06 | sorry i been drinkin haterade all day |

|

Gold Member Username: Wolfman1966WEST MONROE , LOUISIANA USA Post Number: 1021 Registered: Jan-06 | ok guys....get off him and his feet...remember big feet= big weiner |

|

Gold Member Username: Basshead86OG eCoustics Member Post Number: 8551 Registered: Aug-05 | LMAO^^^ |

|

Gold Member Username: Tdeaton1021Near Tampa, Florida USA Post Number: 3351 Registered: Sep-04 | heres some updates!      |

|

Gold Member Username: B101USA Post Number: 3769 Registered: Sep-05 | nice pics Trevor... did u forget to resin the hallway walls leading outside of the port too?? that would also help alot!  looks good tho.... |

|

Silver Member Username: J_baby15Kentucky Post Number: 772 Registered: Feb-06 | Where do u get resin and how much is it? does it make a very noticeable difference in the overall sound? Nice box BTW. |

|

Gold Member Username: Tdeaton1021Near Tampa, Florida USA Post Number: 3356 Registered: Sep-04 | B, no i didn't forget. It's just more complicated to do those areas and its cold outside so I'm giong to wait til tomorrow to do the "hallway". damn, thats good, hallway, i like it.  Jordan-resin can be bought at home depot, lowes, advanced, napa, etc. its about 30$ a gallon. It not only reinforces the walls but creates a really slick surface as you can see so that the air flows more smoothly across the surface. result, less port turbulance, more SQ, more SPL. although there has been rare occasions SPL went down, but I'm going to take that chance lol. who knows, it could have been the temperature of a new day that acutally made it go down or whatever... |

|

Gold Member Username: B101USA Post Number: 3773 Registered: Sep-05 | ok cool... u can also order resin from selectproducts in BULK! http://www.selectproducts.com/ its ALOT different from the automotive type resins u find in those other stores... resin can ONLY help inside a box... giving it a glassed surface.... expect .5-2db gain... just from the resin and box design! I like to mix mine very hott, so it cures in about 5-10 mins... but mixing too hot can make it crack... and start smoking & catch on fire... lol  |

|

Gold Member Username: BestmankindFi AudioBTL Post Number: 7079 Registered: Oct-05 | looking good trevor. you know your sh!t man. you know your sh!t. good job. |

|

Gold Member Username: Tdeaton1021Near Tampa, Florida USA Post Number: 3364 Registered: Sep-04 | Thanks again guys! and B, thanks for that site. i know all stuff bought outside of those stores is better but its easier for me to pick it up. resin doesnt make that big of a difference but things like body filler theres a huge difference between good grade and bad grade. that site has a lot of stuff on it. i've never seen it before, thanks. |

|

Gold Member Username: B101USA Post Number: 3776 Registered: Sep-05 | no prob...  A++ service from them man... they got everything u will need for a project... |

|

Silver Member Username: Oglejust15in re sx, Il Us Post Number: 380 Registered: Aug-06 | so if resin makes it slick... i could use varnish? that makes it slick. |

|

Gold Member Username: B101USA Post Number: 3778 Registered: Sep-05 | use whatever u must, but it wont yeild results like the resin, but would most certainly help! I also heard of people using water sealent stuff b4 also... |

|

Gold Member Username: Basshead86OG eCoustics Member Post Number: 8584 Registered: Aug-05 | looks Good Trevor! keep up the good work. |

|

Gold Member Username: InsearchofbassPost Number: 4957 Registered: Jun-04 | I didnt no the resin could make a .5 to 2 db difference cuz we didnt even resin my dual 6.5 abc box with the tangbands. We should have but it was put together in a rush. 128.6 db in the integra was our best result 2.5 woulda been nice 131.1 db |

|

Gold Member Username: InsearchofbassPost Number: 4958 Registered: Jun-04 | nice work on the box trevor |

|

Gold Member Username: RedlinerWilmington, Ma Post Number: 2889 Registered: Jun-05 | trevor nice job but just rem when u resin it changes the tuning usually like up a hertz or so just letting u know not a big deff but still there lol |

|

Silver Member Username: Andrew571Stillwater/Edmond, Oklahoma USA Post Number: 209 Registered: Oct-05 | that bocks is hawt |

|

Gold Member Username: Tdeaton1021Near Tampa, Florida USA Post Number: 3370 Registered: Sep-04 | thanks everybody! charlie-if tuning is changed the tune goes down not up. if what your going at is the volume is less that is technically true, but the same thickness on the walls will be on the port so less port volume and less turbulance equals lower tune. sean- yeah those guys who first did the tang band box resined it and hit over 130. i wonder if thats what you lack? |

|

Gold Member Username: RedlinerWilmington, Ma Post Number: 2896 Registered: Jun-05 | i heard up from marshall forget the reasoning i could have just remembered it wrong but i think he said up |

Main Forums

Today's Posts- Home Audio Forum

- Home Video Forum

- Home Theater Forum

- Car Audio Forum

- Accessories Forum

- All Forum Topics