Hey Phil check out some pics of the box

|

Silver Member Username: Bump05Hesperia, CA USA Post Number: 117 Registered: Aug-06 | Alright i cut the wood today and blah and the openings for the l7's...im doing the braces tommorow heres some pics and everything came out perfect flush thanks...  http://i11.photobucket.com/albums/a176/xxYupxx/000_0033.jpg http://i11.photobucket.com/albums/a176/xxYupxx/000_0032.jpg http://i11.photobucket.com/albums/a176/xxYupxx/000_0031.jpg ill show you more the more i get finished with it  |

|

Gold Member Username: Dustin3Tigard, OR U.S. Post Number: 3522 Registered: Oct-05 | nice. where are you puttin the braces in the box? and how many? |

|

Silver Member Username: Bump05Hesperia, CA USA Post Number: 118 Registered: Aug-06 | in the middle of the cutouts, and 2 of them |

|

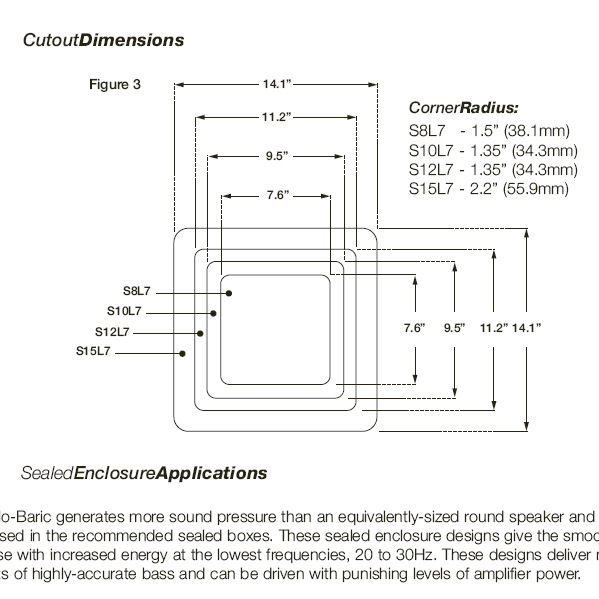

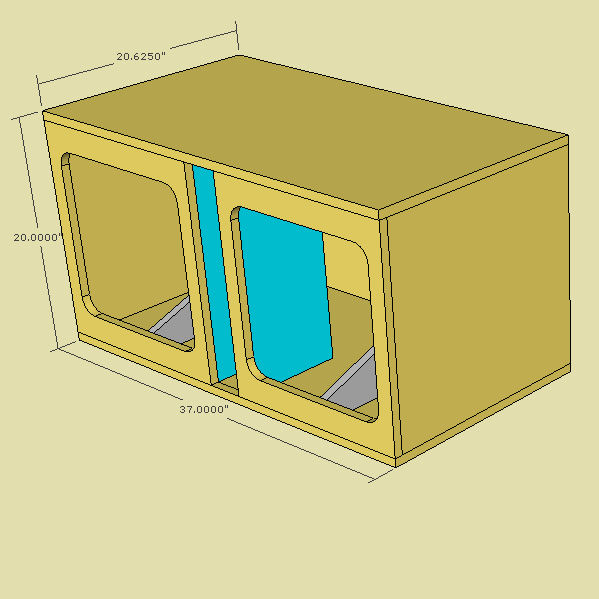

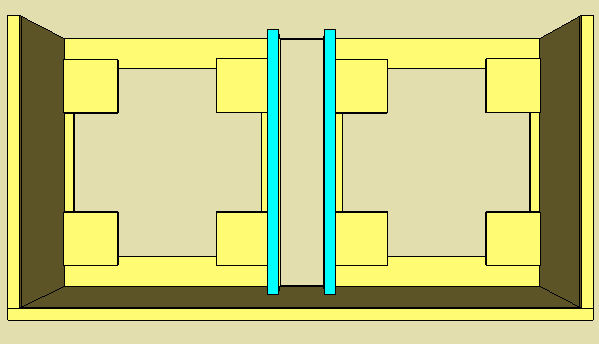

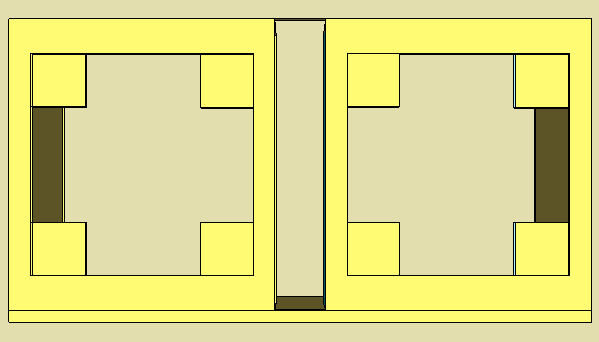

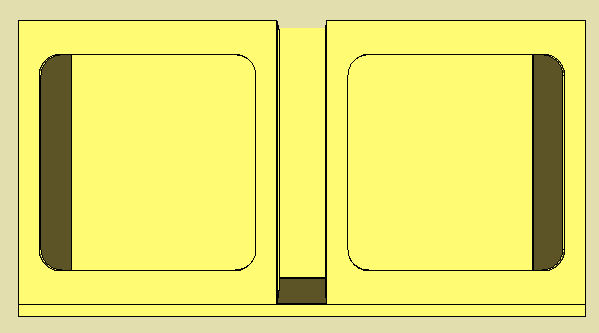

Bronze Member Username: Phil_salisburyPost Number: 88 Registered: Sep-06 | Spl, Your going to kick yourself with what I'm about to say. I posted this in that other thread: "Find center on front baffle, mark layout lines for subwoofer cutout as per Kickers detail. " If you view the pdf file for the S15L7, you will note within it that is states the cutout size along with this info:  Notice the info to the right of the S15L7 cutout dimensions : Corner Raduis - 2.2" Now, look at your cutout, notice anthing?????? When I posted the final enclosure design of the enclosure with the dimensions, I post this:  Notice in the design detail that the cutouts have rounded corners and not square corners. Now, before you start having a conniption fit and wondering what your going to do to fix it short of having to tear it apart or starting over, I already thought it out for the fix. 1. Cut 8 pieces of 3/4" mdf 3 1/2" x 3 1/2" square. 2. cut 8 pieces of 3/4" mdf 4" x 4" square. 3. Attach the 4" x 4" pieces to the back of the baffles butting the edges to the sides & port walls & spaced 5/8" top & Bottom - like this from the inside:  4. Attach the 3 1/2" x 3 1/2" pieces in the front cut out corners, use a sh!tload of wood glue, not liquid nails on edges & backs of the pieces.  Let them dry till the next day. Mark out the corners radius's on the filler blocks and cut with a jig saw - problem fixed.  When I did an enclosure the first time for these Kicker Square subwoofers, I made the same d@mn mistake and this is the same way I fixed it without having to start over. |

|

Bronze Member Username: Phil_salisburyPost Number: 89 Registered: Sep-06 | BTW, Good looking so far, I can't wait to see the rest of it. I know the cutout thing is a setback given all the excellent work so far, sh!t happens, but, it's an easy fix. |

|

Gold Member Username: SouthernrebelMonroe, Louisiana USA Post Number: 3392 Registered: Mar-04 | you would be surprised how many boxes for L7/L5's i see w/ square holes cut. if you cut them no larger than 14.25"x14.25", the L7/L5 will still get a good seal, but like Phil is saying...its alot better the cut the mounting holes w/ a rounded corner. ps, the bottom of a coke can is just about perfect for a template...i have used that on a few L7/L5 15" boxes. perfect fit. |

|

Silver Member Username: Bump05Hesperia, CA USA Post Number: 119 Registered: Aug-06 | sh1t man.i saw that too, but i thought it was either or but yea ill fix, but you sure the squares will stay just by woodglue? then hitting it with a jig wont make em fall off? |

|

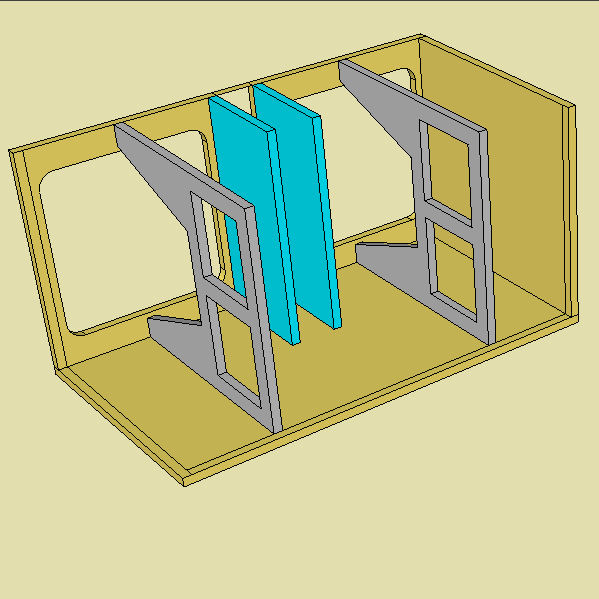

Gold Member Username: Dustin3Tigard, OR U.S. Post Number: 3533 Registered: Oct-05 | i thought he was having a window like bracing for his box? what is that grey thing in the pic? doesnt look like the window thing |

|

Bronze Member Username: Phil_salisburyPost Number: 90 Registered: Sep-06 | Spl, When you attach all the blocking as outline, glue them into place, the blocking as shown in the 1st pic is permanent, you don't remove them, you wont be able to after you glue the blocking on the front to fill in the corner to do the radius cuts. Buy a bottle of Elmer's wood glue or if your using a wood glue to build the enclosure , use the same glue. Believe me, if you do as outline to do the fix, you won't be able to beat them out with a hammer without totally destroying the baffles. A jigsaw will have little effect. You have to give the wood glue enough time to dry, usually 24hrs, but, if your in a hurry to finish this project, 12 hrs will do. |

|

Bronze Member Username: Phil_salisburyPost Number: 91 Registered: Sep-06 | Bass, this the grey thing in the pic:  |

|

Silver Member Username: FrkkevinLake Worth, Texas US Post Number: 834 Registered: Nov-05 | You could do what phil said or just make a new baffle and mount it on the one already existing on your box.. cut the new holes with rounded edges.. all in all you'd end up with a double baffle and a good seal  |

|

Bronze Member Username: Phil_salisburyPost Number: 92 Registered: Sep-06 | I would have to agree with kevin, before you do that, put the bracing in the enclosure so your not driving screws thru 1 1/2" to attach the brace to the baffle. You got the depth because I increased the width and shaved back the depth. |

|

Silver Member Username: FrkkevinLake Worth, Texas US Post Number: 839 Registered: Nov-05 | wish you could work me some magic phil  .. I've got big box dilemnas .. I've got big box dilemnas |

|

Bronze Member Username: Phil_salisburyPost Number: 93 Registered: Sep-06 | Kevin, Yeah, I was looking at you spec's for that enclosure with the 4 ports at various tunings. It no small task to do it given each port is going to displace different volumes for it's tuning frequency. Tell ya what. I willing to do it but, it's not something that going to happen in a day or two, not if you want it done right. |

|

Gold Member Username: BestmankindLos Angeles, CA USA Post Number: 5749 Registered: Oct-05 | i'll let you guys know how awesome phil's boxes are. ima order mine on monday. lol. |

|

Silver Member Username: FrkkevinLake Worth, Texas US Post Number: 860 Registered: Nov-05 | Awesome.. Well its not too bad to do.. I do own a copy of BBP 6.0 but my dilemna was changing my currect box side from 16x30x24 to 16x39x15.5 .. doing so would make the 28 and 35hz ports quite large and have to bend them into the box to get them in.. but then I was thinking about using two ports. One side is plugged for the 45hz and the one one would be openfor the lower notes.. of course this means building twice as many ports and well.. Bah! lol. I might just do a 35hz and a 45hz for starts. The reason for the sudden box change is the current box sets too deep in my trunk and I had a plan to mount the amp in the side. If I did that you would not see the amp much at all and it does have a lot of eye candy so it would have been pointless for me to do what I did to the amp. Not to mention I could then make a simple panel to hide the back of the box from the view and clean the back of the install. The front of the box is eventually going to get sealed off in the trunk by me making a sleeve thats mounted to the trunk behind the rear seats. I can slide the box in and out, mount, or dismount to change something.  |

|

Bronze Member Username: Phil_salisburyPost Number: 94 Registered: Sep-06 | Kevin, That's what makes designing such enclosure's a royal bite. The key is to maintain the enclosure size based on what you want the NET VOLUME to be and then size all the port's accordingly given how much volume is left over from the GROSS VOLUME. Also, you cannot think in terms of trying to maintain the same Port Area for all these ports, that's way you ran into the issue of fitting them. The ports that are tuned lower are going to eat more volume if you don't change the port area. If you want lower port tuning, your going to have to sacrifice port area, granted, that pushes the port vent mach up, but, you have to think realistically if you want everything. |

|

Silver Member Username: FrkkevinLake Worth, Texas US Post Number: 862 Registered: Nov-05 | Well.. Idk what to do.. I thought about building the box tuned to 28hz with the port built into the box. I could make another port on the other side that I can interchange. When I compete just plug the 28hz port and put in whatever port I wanted to use in the other. Would be easier that way and the only volume I'd lose is that taken up by the wood that made the 28hz port. But how would a "blank" port in a box react? It would be like bracing inside the box that is solid instead of having cutouts so how would that effect it? This was the only idea I could come up with that worked given I'm not sure about tuning it to 28hz. I had 2 SX 15"s in a 14 cubic foot box tuned to 28hz and it slammed but now I'm down to a single SX. Currently its in a box tuned to 35hz and it slams but does not drop the lows like it should due to that tuning. How much difference would I see from 35hz - 28hz? Should I leave the daily as a SQL at 35hz? Or tune it lower? |

|

Gold Member Username: BestmankindLos Angeles, CA USA Post Number: 5758 Registered: Oct-05 | why not just build 2 boxes kevin. for daily and comp. |

|

Silver Member Username: FrkkevinLake Worth, Texas US Post Number: 864 Registered: Nov-05 | Because it is a pain in the ass to pull boxes in and out of my car  .. especially alone. Btw check the video thread i posted pics for you lol .. especially alone. Btw check the video thread i posted pics for you lol |

|

Gold Member Username: BestmankindLos Angeles, CA USA Post Number: 5759 Registered: Oct-05 | yeah i saw that. nice. what do you mean pain in the azz? its not like you are going to compete every week. lol. |

|

Silver Member Username: FrkkevinLake Worth, Texas US Post Number: 867 Registered: Nov-05 | I actually compete every 2 weeks on average.. And for that new box design I'd have to pull my backseat out to fit the box in  |

|

Silver Member Username: FrkkevinLake Worth, Texas US Post Number: 868 Registered: Nov-05 | oh and even more pics onw.. lol |

Main Forums

Today's Posts- Home Audio Forum

- Home Video Forum

- Home Theater Forum

- Car Audio Forum

- Accessories Forum

- All Forum Topics